Welcome to May Auto Parts Manufacturing & Supplying (MAPMS)

Welcome to May Auto Parts Manufacturing & Supplying (MAPMS)

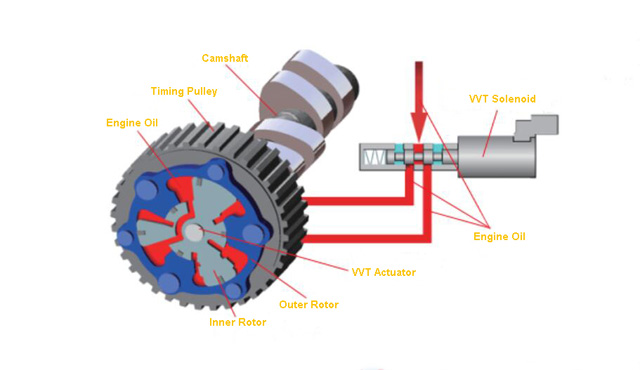

The variable valve timing system VVT works together by the solenoid valve and camshaft timing gear. By changing the camshaft phase of the engine, the intake quality of the engine is positively correlated with the engine speed, so as to achieve the best combustion efficiency and improve the fuel economy. At the same time, the power performance of the engine is also improved. At high speed, the engine needs more air, but the intake valve may close before the required air fully enters, resulting in reduced performance. Therefore, the timing of valve opening and closing is very important.

VVT system is mainly divided into hydraulic type and electronic type.

Hydraulic variable valve timing system, it requires to establish a certain unlocking oil pressure before it can intervene to adjust the engine valve timing. This means that the VVT system cannot work when the engine is idling in most cases. Moreover, the adjustment angle of hydraulic variable valve timing system is limited, and the maximum adjustment angle is usually 35℃ camshaft angle.

Electronic variable valve timing system, it relies on DC motor to drive the camshaft to rotate through the gearbox, independent of engine oil pressure. As long as the power supply can immediately participate in the regulation, and adjustable 360℃.

It adjusts the phase of the engine cam through the equipped control and execution system, so that the opening and closing time of the valve changes with the change of the engine speed, so as to improve the charging efficiency and increase the engine power, also reduce the fuel consumption.

For piston engines, VVT system usually takes in and out air by lifting the throttle valve, which is driven directly or indirectly by the cam on the camshaft. In each intake and exhaust cycle, the cam drives the valve to open for a certain time.

At high speed, the engine needs more air, but the intake valve may close before the required air fully enters, resulting in reduced performance. Therefore, the timing of valve opening and closing is very important. The continuously open valve will cause the fuel to be discharged from the engine without combustion, which will reduce the performance of the engine and increase exhaust pollution. So the idle speed of the competition engine cannot be too low. On the other hand, if the cam keeps the valve open for a long time, as in the case of racing cars, problems will occur at lower speeds.

The crankshaft drives the camshaft through timing belt, gear or chain. The contour and position of the cam on the camshaft are usually optimized for specific engine speed, which usually reduces the torque of the engine at low speed and the power at high speed. Variable valve timing system technology can make it change according to the engine working conditions, and improve the efficiency and power of the engine.

VVT components system consists of ECU, variable valve timing solenoids, VVT actuator, VVT sensor, etc. According to the parameters from VVT components, camshaft speed sensor, intake air flow, throttle position and engine coolant temperature, ECU transmits duty cycle control signal to VVT Solenoid assembly to adjust the oil pressure supplied to VVT actuator.

MAPMS offers the most automotive parts and service to meet customers' needs. ***Please send inquiry with correct OEM numbers.***

The Multifunctionality of the Headlight Combination Switch

READ MORE >

The Multifunctionality of the Headlight Combination Switch

READ MORE >

Auto Electric Fuel Pump: Keep Your Car Full of Power

READ MORE >

Auto Electric Fuel Pump: Keep Your Car Full of Power

READ MORE >

What Do Coil Packs Do On A Car?

READ MORE >

What Do Coil Packs Do On A Car?

READ MORE >